Veolia Mélyépító Magyarország Kft., which is involved in the design and implementation of underground structures related to water utilities and other networks, uses a wide range of no-dig technologies: traditional excavation methods for the construction of galleries and shafts, as well as microtunneling and pipe bursting.

Microtunneling

Microtunneling is a pressing method that can be used to build underground pipelines without excavation. The process is suitable for the construction of drinking water or sewage pipes, but also district heating or telecommunications pipes. The diameter range used by Veolia Mélyépító Magyarország Kft. ranges from 500 mm to 2500 mm, while the length that can be built is unlimited. The cutting head of microtunneling can be changed according to the nature of the existing soil. The pressing debris is transported to the surface as tailings and treated on site by the dedicated part of the equipment before disposal.

Pipe bursting

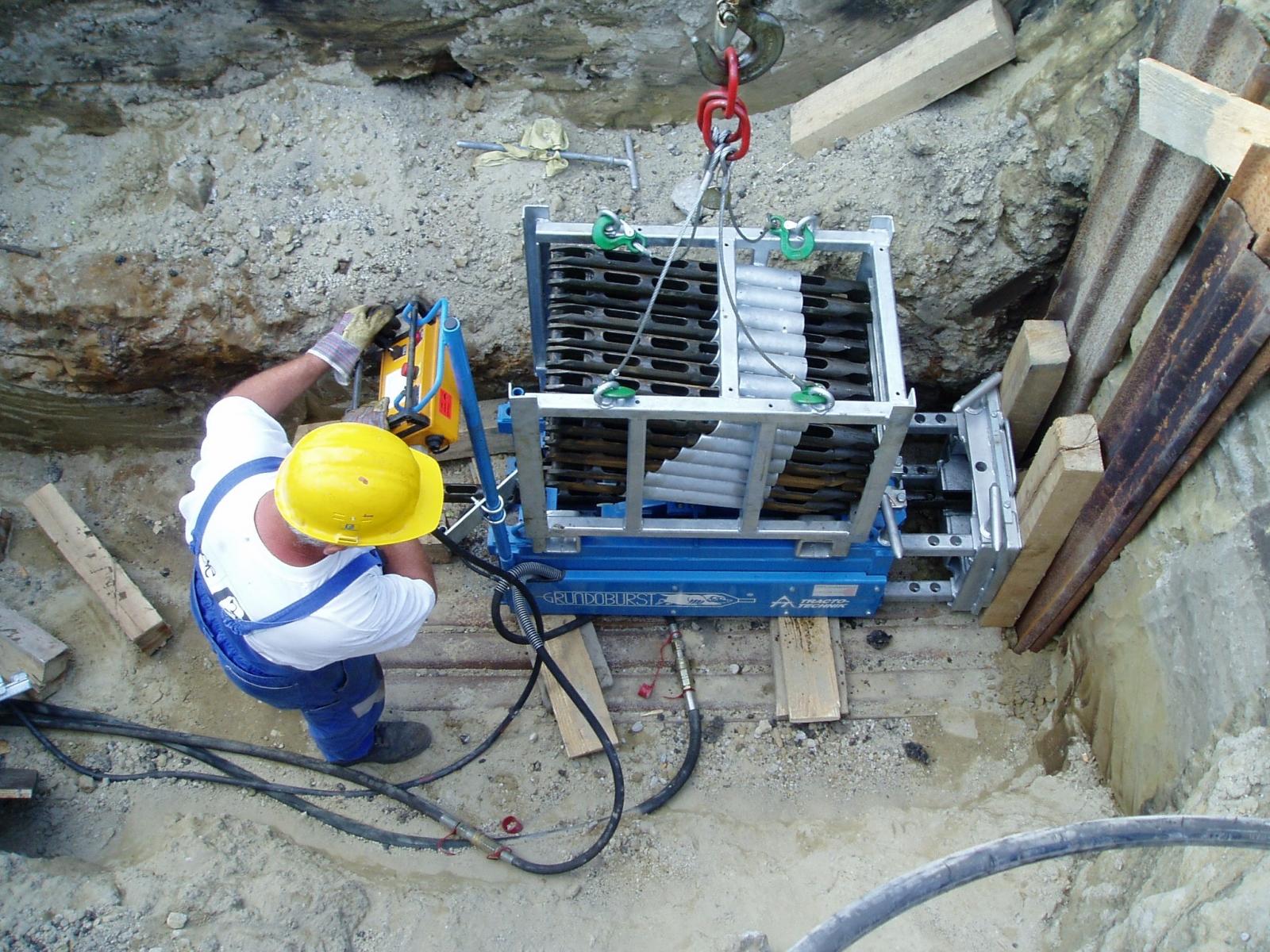

Pipe bursting is a technology used to renovate cast iron, steel and water, sewer and gas pipelines made of plastic. The hydraulic draw bench installed in the shaft to be renovated, and it pushes a pulling rod into a line section designated for line replacement. A new line connected to the splitting/cutting head is installed on the same track as the existing one, pulled back with the rod, with simultaneous cracking of the old line. Due to the extremely fast feasibility and efficiency of this technology, it is being designed and applied more and more often. Our company has been using this NO DIG technology in its construction practice for more than 15 years. Sections 20-100 m long can be made from one pull position. In the past period, more than 20 km of pipeline reconstruction was carried out.

For more information, contact our staff!