GROWING DEMAND FOR WATER

Water is a scarce resource in the Persian Gulf region. During the 1970s, the Saudi government appointed a royal commission to develop the two industrial cities of Jubail and Yanbu. Its goal was to establish infrastructure and facilities that would spur development of a diversified manufacturing base designed to help Saudi Arabia become less dependent on oil revenue. Over time, these two industrial areas have developed an increasingly critical need for water.

A REDUCED IMPACT ON THE ENVIRONMENT

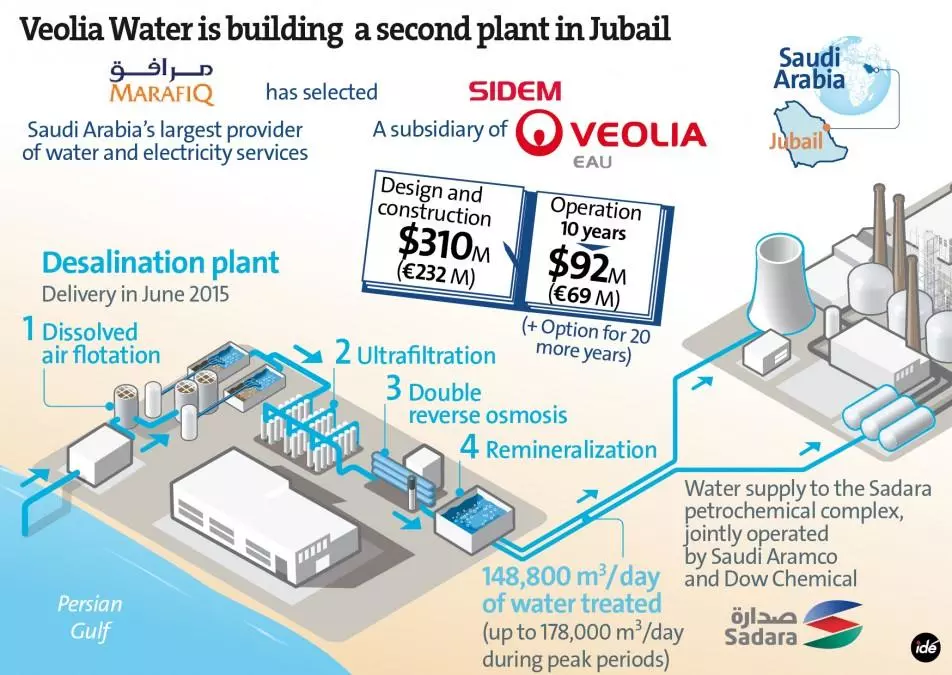

Veolia combines two seawater treatment solutions: ultrafiltration and reverse osmosis, to minimize this new plant’s impact on the environment and meet the very strict water quality standards required by Marafiq. The combination of these various processes will ensure a secure water supply, limit the risk of plant failure and extend its lifespan, while at the same time reducing the site's energy requirements and costs.

With a capacity of 178,000 cubic meters/day, the new plant is scheduled to come on stream in June 2015 and will serve the Sadara petrochemical complex built in Jubail by Dow Chemical and Saudi Aramco.

Johnny Obeid

Vice President - Middle East, Veolia Water Solutions & Technologies

“Thanks to our technology and expertise in operation and maintenance, we can provide significant savings in energy costs.”

Customer benefits

- The desalinated water will be used in the industrial facility’s cooling towers and will also supply the boilers at the site.

Solution

- Process water treatment

Learn how Veolia is resourcing the world

> See how we’re working to save water and energy

178,000 m3 of desalinated water/day

Process water treatment